FormVollendet? Bakelit verändert den Alltag

February 20, 2022 - October 31, 2023

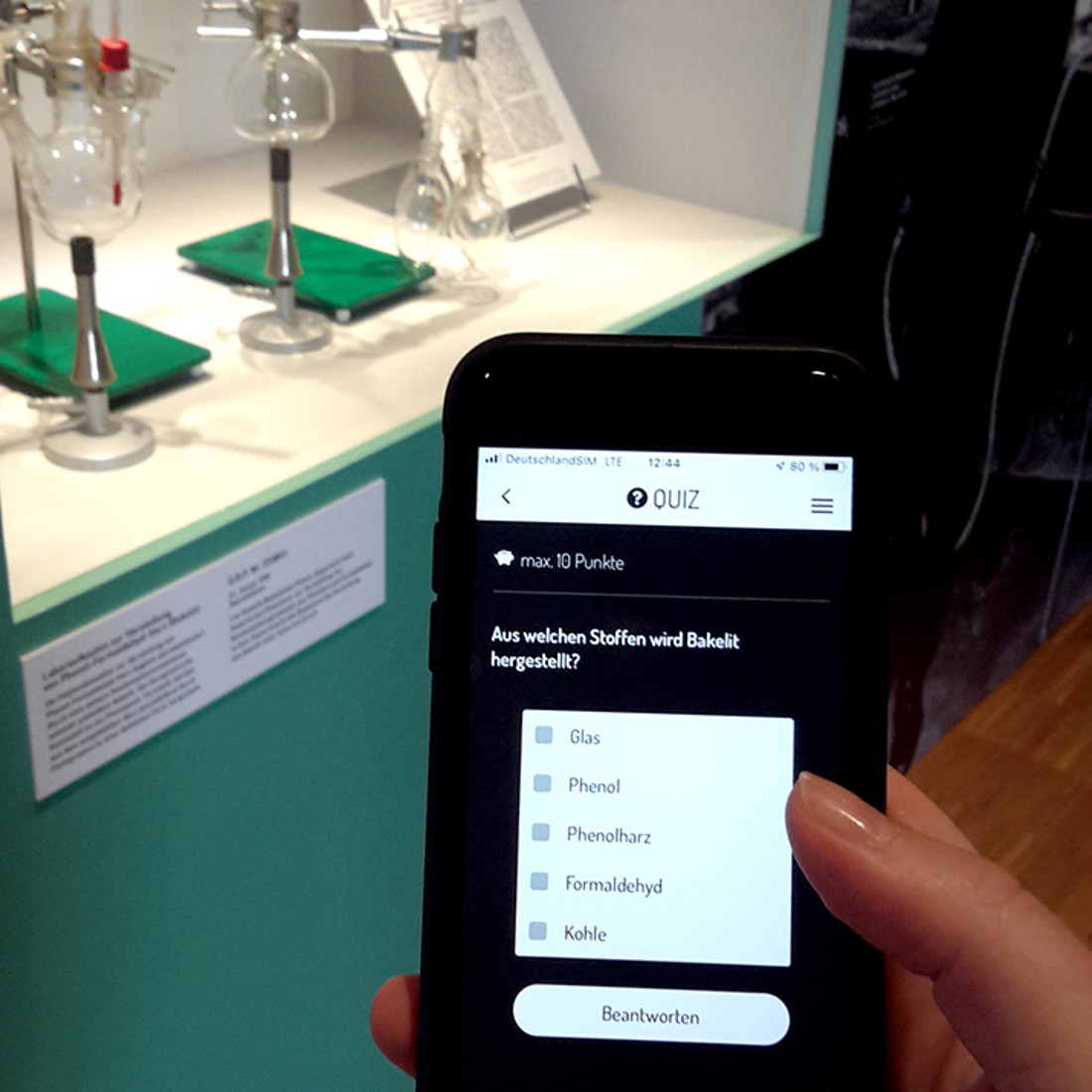

In our new special exhibition “FormVollendet? - Bakelit verändert den Alltag" everything is about the phenolic resin of the "Bakelit" brand. It shows important milestones in the use of phenolic resins, from the development of perfect designs to their practical use in technical areas.

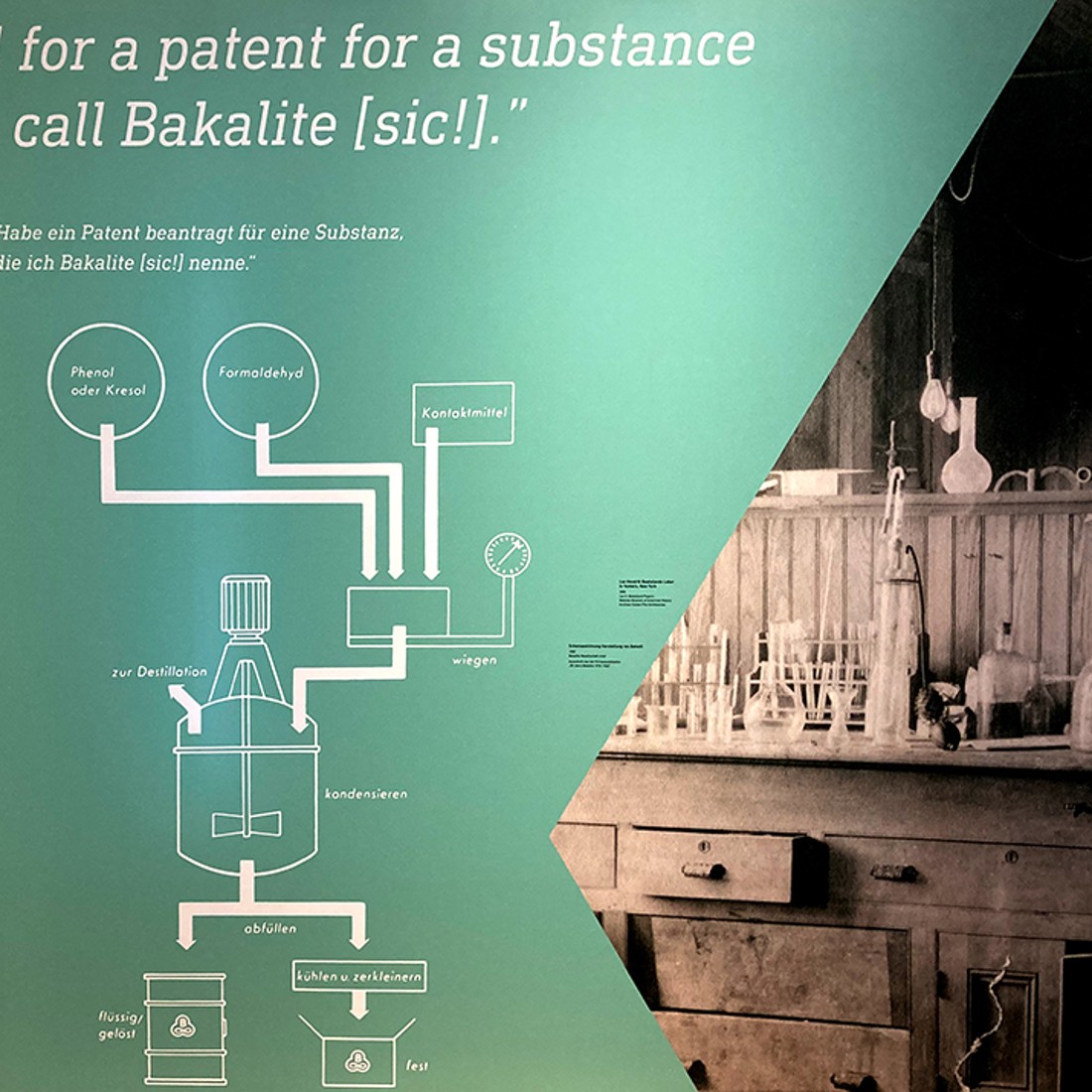

"I have filed a patent for a substance that I will call Bakelite," the chemist Leo Baekeland reported proudly in his diary in 1907. The product range of the material he developed ranged from the socket to the radio to serial house building elements. Strength, insulating ability, acid resistance and heat resistance convinced many customers of Bakelite. Today, phenolic resin products are remembered by many people primarily because of their timeless design. The streamlined design stands for a perfect look.

Flyer and supporting program for download

On the history of Bakelite

The industrialized 20th century increasingly brought about the need for inexpensive materials that could be processed quickly. Serial manufacturing and modern mass production were accelerated by the invention of plastics. The chemist Leo Hendrik Baekeland recognized these signs of the times and registered a patent for his invention in 1907: a phenolic resin that he christened "Bakelite". This could be produced cheaply and quickly in large quantities. Baekeland was soon nicknamed "the father of plastic".

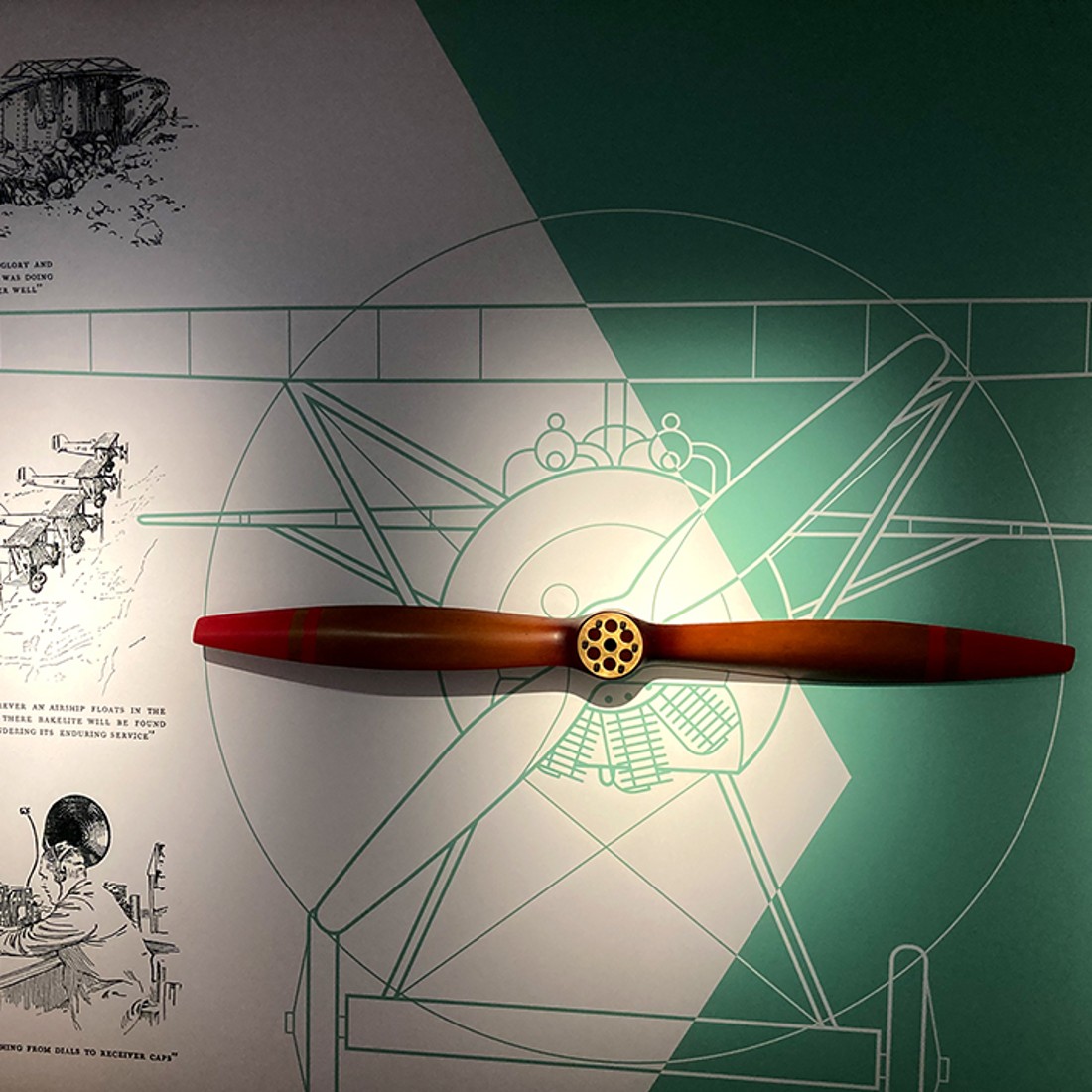

Initially, phenolic resins were used primarily for the manufacture of technical parts such as switches and insulation elements. It was discovered in the 1920s by designers who picked up modern streamlined shapes with molded elements. Just a decade later, phenolic resins had become commonplace on a large scale. After the expiry of Baekeland's patents, other manufacturers now also offered phenolic resin products in a variety of designs. Behind swinging names like "Festellan" and "Philite" there were imitation products that sold well.

The Second World War promoted the use of phenolic resins, particularly in the military sector. The National Socialists used the inexpensive production option to produce the people's receiver, for example, and propaganda praised the material as a German invention. In the post-war period, earth-colored phenolic resins gradually went out of fashion. More colorful and versatile plastics found their way into everyday life, but could not displace Bakelite. Phenolic resin products are still produced today, for example for brake pads and heat shields.

"The Trabant is a sleek, elegant and spirited car" proclaimed the operating instructions for the Trabi-P50 in 1958 with confidence. However, the teasing nicknames "Racing Cardboard" and "Plastebomber", which the car was soon popularly given, revealed the secret of the iconic vehicle: VEB Plasta Erkner, founded in 1948, produced phenolic resins in the GDR under the name Plastadur. The largest customer was the Trabant factory in Zwickau, which manufactured body parts from a phenolic resin-cotton mixture. As a result, the first models of the Trabant weighed little more than 600 kg.